Contract manufacturing

USING OUR MODERN MACHINERY WE ARE READY TO MANUFACTURE YOUR PRODUCT

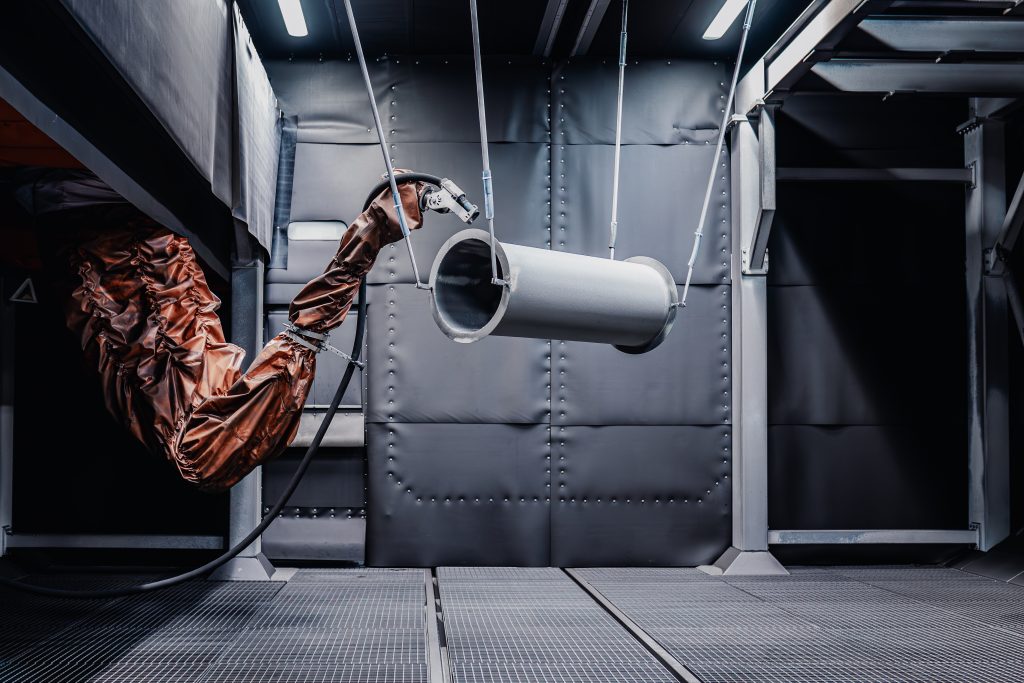

Shot blasting – shot blasting, sand blasting, abrasive blasting; process in accordance with PN-EN ISO 8501, surface quality Sa to Sa 3.

The work is performed at the following positions:

- robotic – elements are transported using the Power & Free system, maximum dimensions of details (width x height x length) 2 000 mm x 2 000 mm x 2 000 mm, maximum weight 400 kg,

- manual – maximum dimensions of details (width x height x length) 2 000 mm x 2 000 mm x 6 000 mm, maximum weight 3 500 kg.

Dry ice – for derusting, degreasing, cleaning:

- robotic – elements are transported using the Power & Free system, maximum dimensions of details (width x height x length) 2 000 mm x 2 000 mm x 2 000 mm, maximum weight 400 kg,

- manual – maximum dimensions of details (width x height x length) 2 000 mm x 2 000 mm x 4 000 mm, maximum weight 2 000 kg.

Painting – anti-corrosion protection, hydrostatic spray painting in accordance with PN-EN ISO 12944-5 with epoxy, polyurethane and alkyd paints.

The work is performed at the following positions:

- robotic – elements are transported using the Power & Free system, maximum dimensions of details (width x height x length) 2 000 mm x 2 000 mm x 2 000 mm, maximum weight 400 kg,

- manual – maximum dimensions of details (width x height x length) 2 000 mm x 2 000 mm x 6 000 mm, maximum weight 3 500 kg.

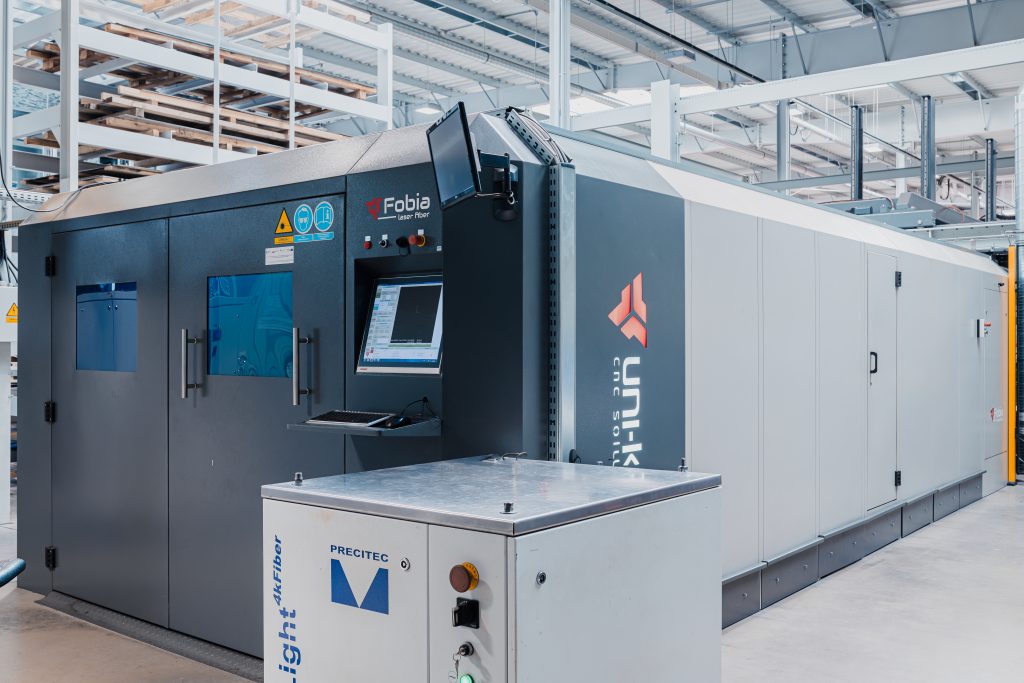

Laser cutting – automatic sheet feeding of carbon steel, stainless steel, acid-resistant steel, galvanized steel, etc., maximum sheet size 2 000 mm x 6 000 mm or maximum weight 500 kg, sheet thickness range from 0,6 to 15 mm.

Plasma cutting – plasma cutting of carbon steel, stainless steel, acid-resistant steel, galvanized steel, etc. with coils or manual loading.

Maximum sheet size 1 500 mm x 6 000 mm.

Thickness of galvanized sheets from 0,6 to 1,25 mm (from coils) or thicker in sheets.

Bending – bending of metal sheet using bending and edging machines:

- automated – sheet width 750 – 2 000 mm, length up to 6 000 mm, sheet thickness up to 3 mm. The bending process allows to make almost any closed profile, e.g. a rectangle, a hexagon, with a circumference of up to 6 000 mm with one longitudinal weld,

- manual – maximum bending length 6 000 mm with a thickness of 3 mm (5 mm with shorter bending length).

Bending machines – maximum bending length 4 000 mm with a sheet thickness of 4 mm (maximum 6 – 8 mm with shorter bending length).

Roll-bending – sheet metal roll-bending in the process:

- automated – sheet size 750 – 2 000 mm, length up to 6 000 mm, thickness up to 4 mm, diameter 300 – 1 900 mm (rolling from one sheet),

- manual – maximum sheet width 2 000 mm, maximum thickness 2 mm, minimum diameter 140 mm.

MAG welding (135) – in accordance with PN-EN ISO 5817 at the station:

- robotic with a rotary-tilting manipulator:

o single-axis – maximum

dimensions of details (width x height x length)

2 000 mm x 2 000 mm x 3 000 mm, maximum weight 2 000 kg,

o biaxial – maximum

dimensions of details (width x height x length) 2 000 mm x 2 000 mm x 2 000 mm,

maximum weight 2 000 kg,

o biaxial – maximum

dimensions of details (width x height) 1 000 mm x 1 000 mm, maximum weight 500

kg,

- manual – without any significant limitations.

Among others we have following certificates:

- EN-ISO 9001:2009

- PN EN-ISO 14001:2005

- PN-ISO 45001:2018-06

- DIN EN ISO 3834-2

- ISO 19443:2018

For pricing purposes we accept drawings in dwg, dxf, ipt, iam, stp, rvt, nvm formats as well as hand sketches and pdf.

We provide assistance in construction in Inventor and Autocad.

Deviations from the a.m. process limitations could be mutually agreed.