Certificates

SELECTED CHOICE OF CERTIFICATES

Quality management system for welding

KMW Engineering meets the requirements of EN ISO 3834-2:2021-09, Quality Management System for fusion welding. Our system is certified by the TÜV NORD Polska Sp. z. o.o. The quality of the welding processes is verified once a year during third party audits and recertification takes place every 3 years.

Scope of certification: Processes related to welding of metallic materials in field of ventilation system.

Material groups: 1.1, 1.2, 8.1 acc. to ISO/TR 15608 and galvanized steels acc. to EN 10348.

Welding processes: 111, 135, 141, 212.

Responsible welding coordinators: Aleksandra Kosik (PL / IWE / 3365 / 2022), Leszek Marchel (PL / IWS / 658 / 2016).

Occupational health and safety

KMW Engineering meets the requirements of ISO 45001:2018: “OHS Management Systems” in design, production and execution of ventilation and air-conditioning systems. Since 2021, together with the Environmental Management System, it constitutes an integrated management system (ITB – 040 / ŚB).

Our system was certified by the Certification Department, Building Research Institute in Warsaw.

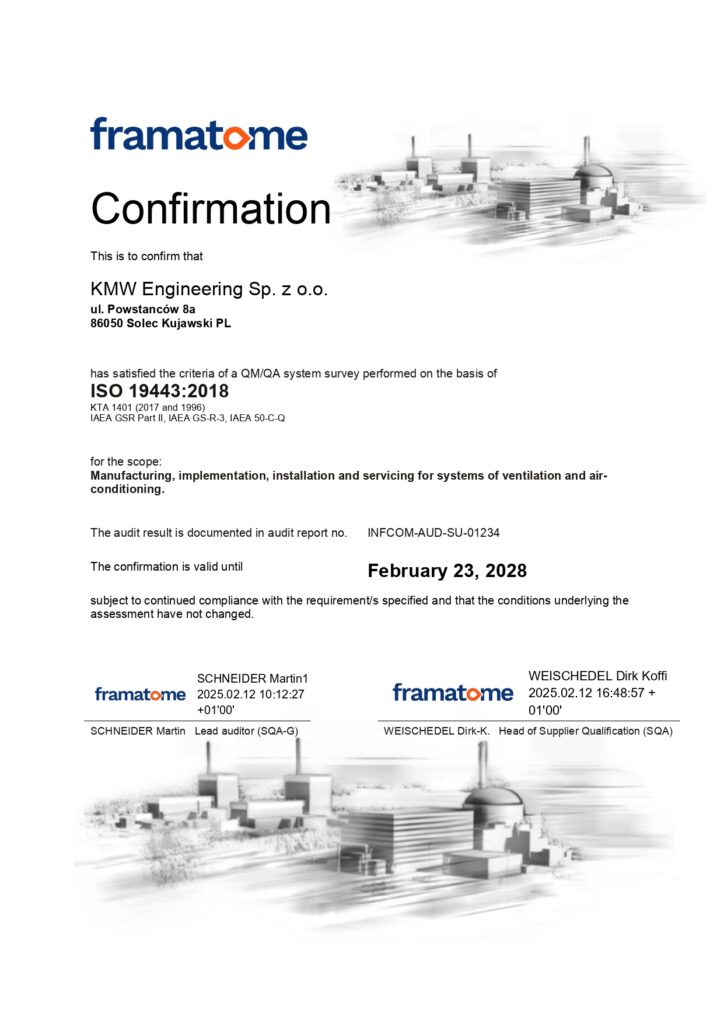

Nuclear power production management system

KMW Engineering manages a certified Quality Management System in Nuclear Power Industry conforming to QN 100 (former KTA 1401). Certification is performed by thecompany AREVA, specialising in construction and modernisation of nuclear powerplants. Regular verification audits confirm the quality of our processes.

2025

Recertification of the quality management system in nuclear standards in accordance with ISO 19443:2018, KTA 1401, IAEA 50-C-Q, IAEA GS-R-3 and IAEA GSR Part 2 standards.

2022

Recertification of the quality management system in nuclear standards in accordance with ISO 19443:2018, KTA 1401, IAEA 50-C-Q, IAEA GS-R-3 and IAEA GSR Part 2 standards.

2016

Our quality management system has been expanded with requirements concerning additional areas:

• Environmental management according to ISO 14001,

• Occupational health and safety management according to OHSAS

18001,

• Welding quality management according to ISO 3834-2,

• Nuclear quality management according to NSQ 100 and KTA 1401.

We successfully pass the fourth audit concerning meeting European nuclear safety requirements and recommendation of the International Atomic Energy Agency, IAEA GS-R-3 and IAEA 50-C-Q. Over 15 years

of experience in construction of nuclear facilities and 9 years of certified

accreditation confirming quality of nuclear safety qualifies KMW as a

recommended supplier and contractor for the nuclear power sector.

2013

Recertification of the Quality Management System in Nuclear Power Industry valid to 2016, confirming the requirements of QN-100 in design, implementation, installation and maintenance of ventilation and airconditioning systems.

2010

Recertification of the Quality Management System in Nuclear Power Industry valid to February 2013, confirming the requirements of KTA 1401, IAEA 50-C-Q and FRA/N/100/OL3 in design, implementation, installation and maintenance of ventilation and airconditioning systems.

2007

Certification of the Quality Management System in Nuclear Power Industry valid to February 2010, confirming the requirements of KTA 1401, IAEA 50-CQ and FRA/N/100/OL3 in design, implementation, installation and maintenance of ventilation and airconditioning systems.

Environmental management system

Since 2012 KMW Engineering meets the requirements of the EN ISO 14001: 2015 standard: “Environmental Management Systems” in design, production and execution of ventilation and air-conditioning systems. Since 2021, together with the OHS Management System, it constitutes an integrated management system (ITB – 040 / ŚB).

Our system has been certified by the Certification Department of the Building Research Institute in Warsaw.

LT2 Inspectors

KMW has 5 LT2 inspectors according to EN ISO 9712. This certification is intended for persons conducting leak tests during manufacturing and in-service. The second level of certification means that an employee is not only authorised to perform tests, but also to supervise processes.

KMW Laboratory

The certificate issued by the Building Research Institute confirms that the Leak Tightness Tests Laboratory LTTL has technical competencies conforming to the requirements of EN ISO 9001 for leak tests in accordance with EN 12237, EN 1507, EN 1886 and for painting test in accordance with EN ISO 12994-7, EN ISO 2808, EN ISO 16276-1+2, EN ISO 2409.

Furthermore, the company ensures the Laboratory is independent of production departments and working relationships do not affect reliability of tests results in any way. This confirmation is recertified every 3 years.

Quality management system

KMW Engineering meets the requirements of EN ISO 9001:2015, Quality Management Systems. Our system was certified by the Certification Department, Building Research Institute in Warsaw (PCA accreditation).

Implementation of the Quality Management System in accordance with the amended European Standard falls in line with our Quality Policy. Regular verification audits confirm process quality, with recertification taking place every 3 years.

2024

Quality Management System recertification (No ITB – 024/S) confirming the requirements of EN ISO 9001:2015 in design, production, construction, of ventilation and air conditioning systems.

2021

Quality Management System recertification (No ITB – 024/S) confirming the requirements of EN ISO 9001:2015 in design, production, construction, of ventilation and air conditioning systems.

2018

Quality Management System recertification (No ITB – 024/S) confirming the requirements of EN ISO 9001:2015 in design, production, construction, of ventilation and air conditioning systems.

2015

Quality Management System recertification (No ITB – 024/S) confirming the requirements of EN ISO 9001:2009 in design, production, construction, delivery, installation and maintenance of ventilation and air conditioning systems.

2012

Quality Management System recertification (No ITB – 024/S) confirming the requirements of EN ISO 9001:2009 in design, production, construction, delivery, installation and maintenance of ventilation and air conditioning systems.

2009

Quality Management System recertification (No ITB – 024/J) confirming the requirements of PN-EN ISO 9001:2006 in design, production, construction, delivery, installation and maintenance of ventilation and air conditioning systems.

2006

Quality Management System certification (NoITB – 024/S) confirming the requirements of PN-EN ISO 9001:2001 in design, production, construction, delivery, installation and maintenance of ventilation and air conditioning systems.

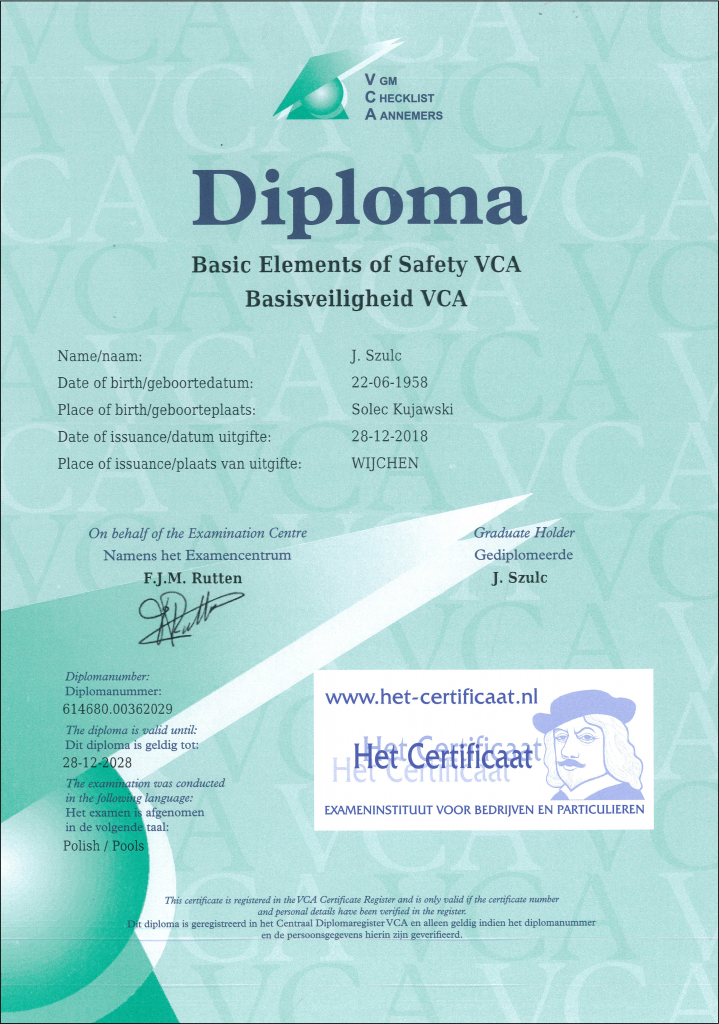

Installation - SCC Certificates

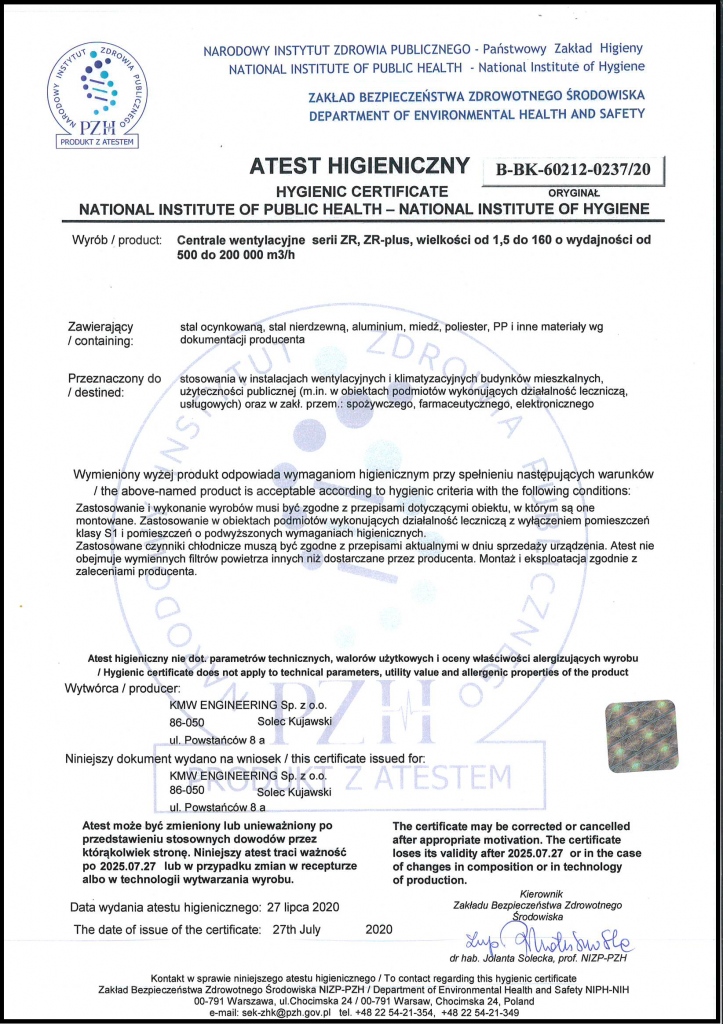

Air handling units

Air handling units manufactured by KMW Engineering were certified for their mechanical durability, tightness, and heat and noise transfer.

Due to the fact that we made custome-made units no further certification was needed.

During over 20 years of production, they underwent procedures confirming meeting of requirements and approving them for use by:

- COBRI INSTAL Warszawa 2004: EN 1886 Conformance Approval

- ENERGOAUDYT Gdynia 2005: Conformance of EN 1886 requirements

- ENERGOAUDYT Gdynia 2005: Electromagnetic Compatibility Certificate EMC

- PZH Warszawa 2010: Certificates of Hygiene for air processing units, series KMW ZR and ZS

- PZH Warszawa 2010: Certificate of Hygiene for applications in “clean facilities”

- UTP Bydgoszcz 2014: Confirmation of model tests in accordance with EN 1886

- GOST-R Moscow 2014: Manufacturer certificate for air processing units, series Z

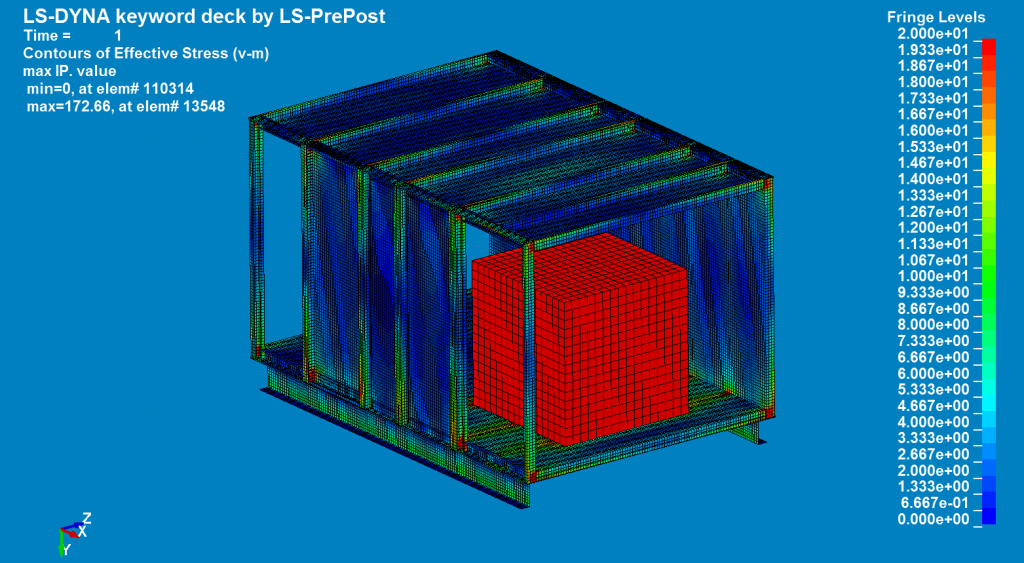

Earthquake resistance test

Resistance of KMW Engineering air handling units was tested for seismic conditions in Finland. These tests are always specific for a spectrum characteristic for a given location.